Mark-10 Series F Heavy Capacity Test Frames, F755(S) and F1505(S) with EasyMESUR

Series F test frames with EasyMESUR® are engineered to perform a wide range of tension and compression tests, including break testing, cycling, limit testing to a load or distance, load holding, average force testing, and more. Note: Force sensors sold separately. You must order at least one force sensor to have an operational system.

Set up and run tests, export results, and create a report via the integrated, easy-to-use touchscreen interface – no PC or force gauge required. For unique needs, run the tester from a PC with your own custom application utilizing EasyMESUR®’s serial command library.

Sample setup and fine positioning are a breeze with available FollowMe® force-based positioning – using your hand as your guide, push and pull on the force gauge or load cell to move the crosshead at a variable rate of speed.

Engineered around a modular function platform, the EasyMESUR® run screen can be arranged with large, simple controls – or configured for more advanced applications with a selection of optional functions, including distance measurement, graphing, cycling, and more. Purchase functions and packages at time of order or enable them in the field via activation codes. All testers are shipped in a 160-hour evaluation mode, in which all functions are available.

Generous travel, clearance, and depth dimensions accommodate samples of various shapes and properties. Modular mechanical design accommodates single- and double-column extensions for oversized specimens.

Select from vertical or horizontal orientations, along with a broad range of force sensor capacities and an expansive array of grips and fixtures.

Rigid and precise by design

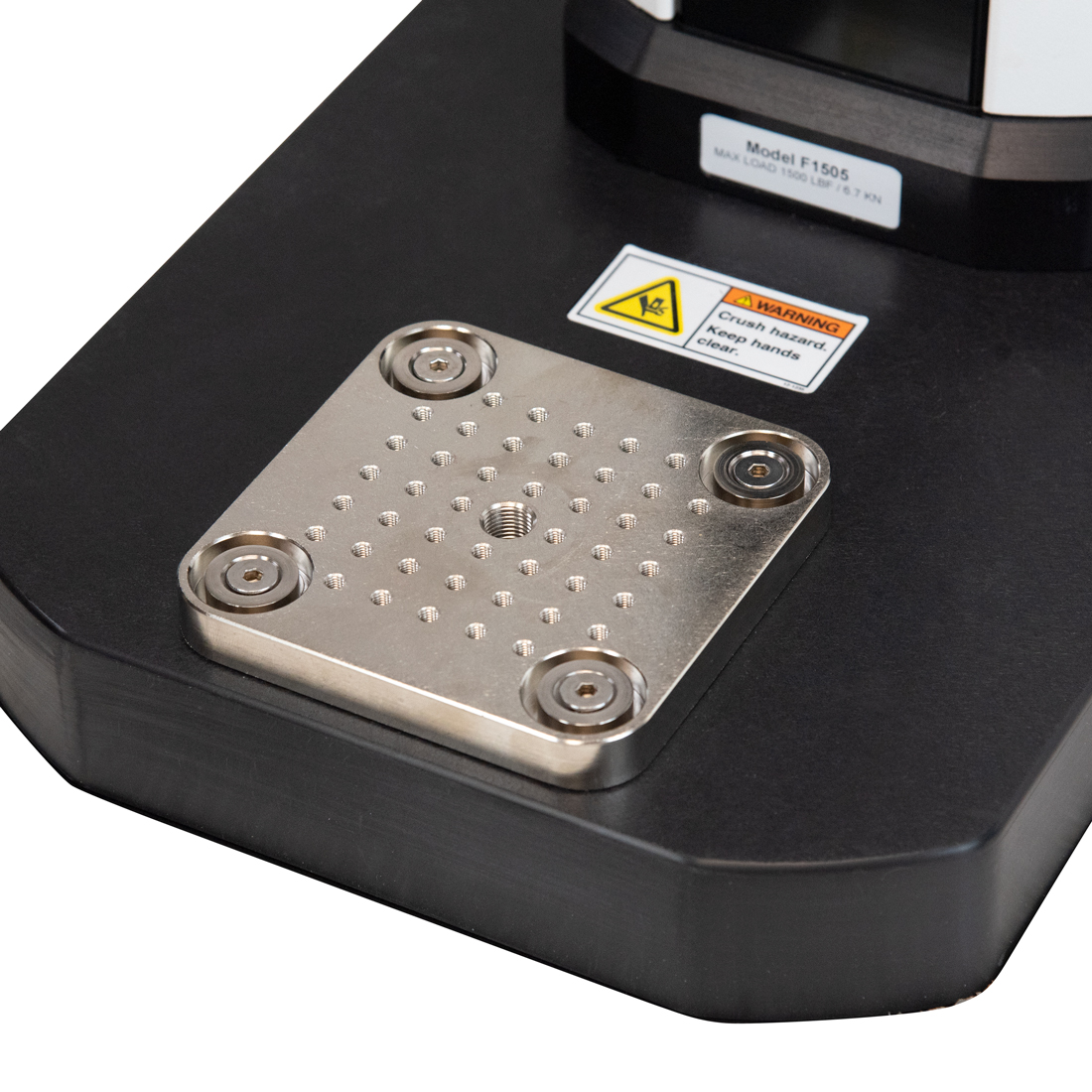

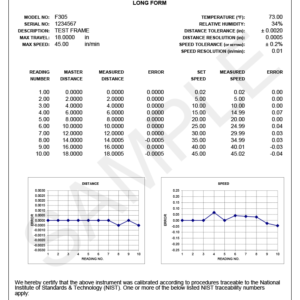

Exceptionally rigid frames feature custom extrusion designs, engineered for stiffness. Factory compensation of test frames and force sensors ensure position accuracy of ±0.006 in / 0.15 mm under any load, at any position.

Stepper motors and controllers drive a ballscrew and linear guideway for smooth, quiet operation, with virtually no speed variation under load.

Conveniently modular

Frame bases can be removed to accommodate column extensions and alternative mounting configurations. Most electronics are housed in a self-contained enclosure, easily accessed and replaced if needed. Integrated T-slots along the column accommodate add-ons.

Limit switches

Solid-state upper and lower limit switches may be used as test limits or as test exceptions. Dual-graduated rulers aid in switch placement.

Series MR07 force sensors measure tension and compression forces, and are designed for Series F test frames. With Plug & Test® technology, all configuration and calibration data is saved within the sensor, allowing it to be calibrated on the test frame or off-site with a Mark-10 indicator.

Ranges available from 50 to 1,500 lbF [250 N to 7.5 kN].

Compatible with Models F755, F755S, F1505, and F1505S test frames. Not compatible with Models F105, F305, F505, and F505H.

Easy-to-service electronics

Most electronics are housed in an integrated module, easily replaced without special tools or processes.

The EasyMESUR® integrated control panel centralizes test setup, test frame control, and data collection into one convenient place. Use the 7” touchscreen to create and run a wide range of tests, including:

The EasyMESUR® integrated control panel centralizes test setup, test frame control, and data collection into one convenient place. Use the 7” touchscreen to create and run a wide range of tests, including:

- Test to a load

- Test to a sample break

- Test to a distance

- Load holding

- Cycle testing

- Average force testing

View data in graphical format or results tables. Save or export data as needed, or generate a report.

What’s your point of view?

Run a test via the Standard, Graph, or Results views, and switch views as needed. Pass / Fail indicator easily identifies problematic samples.

Standard View

View large-format load and distance values, with pass/fail status.

Graph View

View a graph of load vs. distance or time, with pass/fail status.

Results View

View results for each run, with corresponding statistics for the results.

Test setup is easy as 1-2-3

Basic tests

Select a test type, and EasyMESUR® will guide you through the setup.

Load Limit

Load Limit

Distance Limit

Distance Limit

Break Limit

Break Limit

Load Hold

Load Hold

Cycle

Cycle

Averaging

Averaging

1. Basic Test Settings

- Test direction

- Speed

- Test-specific parameters

- Data save preferences

2. Results Settings

- Select results

- Enable and configure pass/fail limits

- Set data collection rate

- Set auto-return to home

3. Graph Settings

- Single-point vs. continuous graphing

- Set load vs. time or vs. distance

- Graphing start threshold

Robust data acquisition and management

Blazingly fast

Force sensor sampling rate of 5,000 Hz yields accurate peak measurements even in quick-duration events. EasyMESUR® collects load and travel data at up to 100 Hz, and allows up to 100,000 data points per run.

Customizable reporting

Print or create a PDF report, including results, statistics, graph, system and user information, and comments.

Create report templates to save with future reports.

Save or export data

Save individual runs and results to a USB drive or internal storage within the control panel.

Results sets and data from individual runs may also be exported as .csv files.

Intelligent manual control

Manually control the test frame to obtain quick load and distance results, or manually position the crosshead prior to a test. Select from several actuation methods, including momentary (button-hold), maintained (button release) motion, jog mode with three distance presets, and FollowMe® force-based positioning.

Push and pull on the force sensor to move the crosshead. Apply greater load to achieve faster motion. FollowMe® is responsive enough for quick positioning as well as fine adjustments.

Calibrate force sensors on the test frame or off-site

Calibrate sensors in one of two ways:

Test frame

EasyMESUR® provides an integrated utility, with an intuitive step-by-step wizard. Manual controls allow the technician to use the test frame to apply tension and compression forces.

Off-site

Conveniently remove the force sensors for off-site calibration with a Mark-10 Model M7I or M5I indicator (requires optional AC1083 adapter).

Secure user access

Control user access to sensitive areas, such as test editing and calibration via password.