Moisture Balances

Water is essential to life; it plays a critical role in the physical and chemical functions of our bodies, the food we eat, and the materials that surround us. In many industries it is important—if not critical—to measure the water content of substances in order to assess quality, adjust manufacturing processes, and ensure that products meet regulations and guidelines.

The amount of available water dictates the shelf life and stability of many systems; for example, the presence of water in food greatly impacts its susceptibility to chemical, enzymatic, and microbial activity.

Water content is also important for the processing and handling of:

- Cosmetics

- Pharmaceuticals

- Food

- Personal care products

- Pulp and paper products

- Specialty chemicals

Measuring the amount of water contained in certain materials can be very difficult due to the complexity of the water molecule and its strong intermolecular bonding capabilities. In most cases, measurement of water is better defined as the measurement of moisture content, defined as the mass of water per unit mass of dry material.

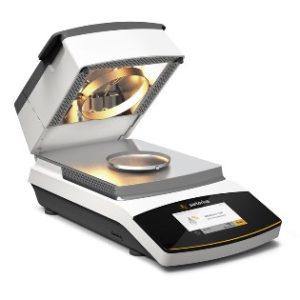

The Ohaus, Sartorius and A & D moisture balance (or moisture analyzers) that we offer measure moisture thermogravimetrically.

Thermogravimetric moisture analysis defines moisture as the loss of mass observed when the sample is heated and is based, in theory, on the vaporization of water during the drying process; this measurement does not distinguish weight loss of water from loss of volatile components or sample decomposition. For this reason, moisture content as measured by thermogravimetric techniques includes all substances which vaporize when heating a sample and are measured as weight loss during the heating process. Therefore, we use the term “moisture content” rather than “water content” when using a thermogravimetric device.

Moisture balance are excellent tools for routine analysis in the process environment. The instruments are rugged, simple to operate, and provide rapid, reliable data. The devices may also be used in the research laboratory as an investigative tool for basic scientific studies.

Certain precautions should be taken to ensure that measurements made with the devices are reproducible and as accurate as possible. The following are some suggestions for controlling operating variables for moisture balances:

Allow adequate cooling between sample runs. If the machine is still very hot from the previous run, it may affect the initial weight reading of the sample and cause inaccuracy in the final calculation

Keep starting weight for test material consistent. Since the final reading (weight) is a factor of the drying process, consistent starting weight will minimize differences due to physical parameters of sample introduction and drying profile.

When possible, try to control the laboratory environment. For extremely sensitive samples or for cases where sensitivity in reading is critical, consider working in an environmental chamber where temperature and humidity are tightly controlled. In general, it is best to set up the instrument in an area free of windows to minimize exposure to temperature extremes, drafts, and other environmental conditions.

In order to maintain competitiveness, quality control is critical for most companies—and a moisture balance is an important part of your quality control system. The majority of the moisture balance that we offer are designed to be either easily integrated into a general quality system such as GLP/GMP.

Our knowledgeable sales representatives are ready to answer your questions about product specifications, features, performance, and benefits. Whether it is a new purchase, rental, repair or calibration, Our goal is that prompt order delivery, quick turnaround, and easy access to technical support is always within reach. Consider your quest for Moisture balance a success.

-

FREE SHIPPING

Ohaus MB32 Moisture Balance

MSRP: $3,416.00NOW: $2,903.60See Price in Cart!Buy Now This product has multiple variants. The options may be chosen on the product page -

FREE SHIPPING

Ohaus MB92 Moisture Balance

MSRP: $5,072.00NOW: $4,311.20See Price in Cart!Buy Now This product has multiple variants. The options may be chosen on the product page -

A&D M Series Moisture Analyzers Series

MSRP: $2,895.00Now: $2,171.25Buy Now This product has multiple variants. The options may be chosen on the product page -

FREE SHIPPING

Ohaus MB62 Moisture Balance

MSRP: $4,347.00NOW: $3,694.95See Price in Cart!Buy Now This product has multiple variants. The options may be chosen on the product page -

Free shipping

Ohaus MB27 Moisture Analyzer

MSRP: $3,231.70Now: $2,699.00Buy Now This product has multiple variants. The options may be chosen on the product page -

Free Shipping

Ohaus MB90 Moisture Analyzer

MSRP: $4,331.60Now: $3,599.00Buy Now This product has multiple variants. The options may be chosen on the product page -

Please contact us for Pricing & Availability

Sartorius MA160 Advanced Moisture Analyzer

MSRP: $5,680.00Now: $4,828.00Buy Now This product has multiple variants. The options may be chosen on the product page -

Please contact us for Pricing & Availability

Sartorius MA37 Moisture Analyzer

MSRP: $4,420.00Now: $3,978.00Buy Now This product has multiple variants. The options may be chosen on the product page