Mark-10 IMF002 Materials Testing Calculations Module for F series test stand.

Characterize and analyze the behavior of materials, components, and assemblies with a suite of materials testing calculations, including:

- Stress and strain

- Tensile strength

- Shear strength

- Young’s modulus (auto-calculate or manually draw)

- Yield point

- Offset yield (user-specified percentage)

- Rupture

- Percent elongation

- Flexural modulus

- Force per unit width

- Wide variety of results based on the above calculations, such as stress at maximum strain, strain at rupture, etc.

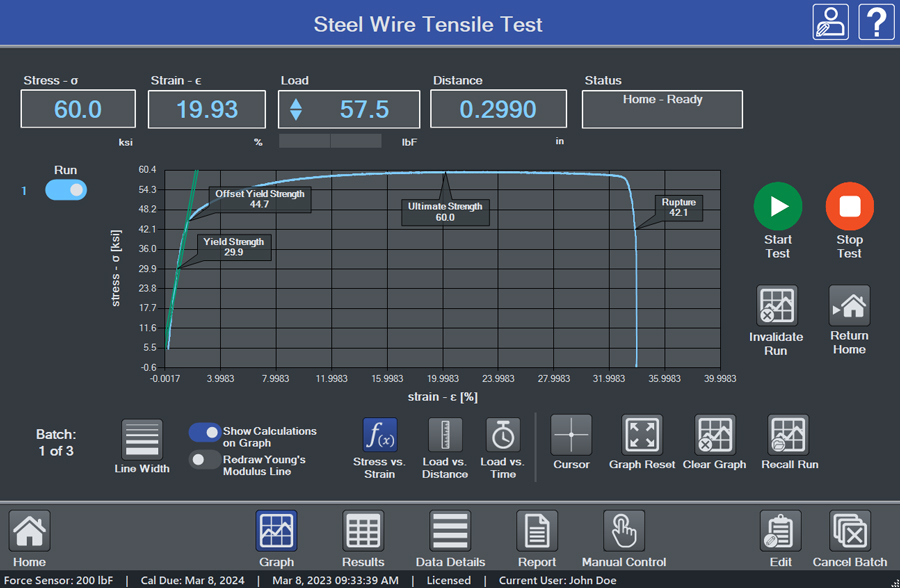

IntelliMESUR® formats calculations into a Results table, with corresponding statistics for multiple runs. View a stress-strain curve with annotated calculations. Display up to 10 runs simultaneously for visual comparison.

Common materials testing calculations include:

Stress

Stress equals force divided by the cross-sectional area of the sample, commonly measured in psi or MPa.

Strain

Strain is the percentage deformation of a sample while under load, measured from its original length between the grips.

Young’s Modulus

Young’s modulus, otherwise known as modulus of elasticity, is the slope of the elastic portion of a stress-strain curve.

Yield Strength

Yield strength is the amount of stress that can be developed in a material without causing plastic deformation; in other words, the transition point from elastic to plastic behavior.

Offset Yield Strength

Offset yield strength approximates a stress just beyond the elastic limit. Draw a parallel line to the Young’s Modulus, offset by a specified amount, commonly 0.2%, and identify the intersection point along the stress-strain curve.

Ultimate Strength

Ultimate strength refers to the maximum observed stress during the test.

Rupture

Rupture is the amount of stress at which the sample breaks. A break can be defined as a specified percentage of drop from the ultimate strength.

Note: Calculations are not available for multi-step tests.