| AF008 |

Crosshead movement responds to manually pushing or pulling on the force gauge shaft or load cell. Increasing force produces greater speeds. Ideal for setups and quick positioning. |

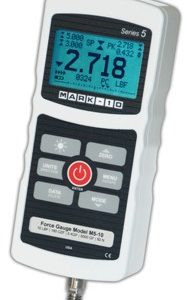

- Series 7 or 5 gauge or indicator with load cell

- 09-1214 interface cable

|

| AF009 |

Travel is indicated on the control unit display, with output via USB. An internal scale utilizing Renishaw technology produces significantly higher accuracy than with conventional rotary encoder-based designs. Backlash and nonlinearity are virtually eliminated. |

- Field hardware installation required.

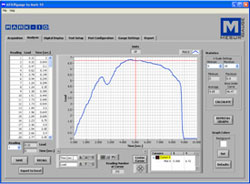

- If data output to a PC is required, add 09-1214 and 09-1158 cables, and a Series 7 or 5 gauge or indicator with load cell.

|

| AF010 |

The ESM303 may be fully controlled by a PC through a custom-written program in any language supporting ASCII communications. Also responds to the legacy Chatillon TCD command set and legacy Nexygen TCD software (not available from Mark-10). |

- Series 7 or 5 gauge or indicator with load cell

- AF009 travel indication

- AF011 programmable travel set points

- 09-1214 interface cable

- 09-1158 USB output cable

|

| AF011 |

The stand stops at or cycles between programmable upper and lower travel distances. |

- AF009 travel indication option

|

| AF012 |

Protects a force gauge or force sensor against overload. Program the desired percentage of full scale of the gauge. Adjustable analog voltage setting allows the stand to interface with virtually any gauge with analog output. |

- Series 7 or 5 gauge or indicator with load cell

- 09-1214 interface cable

|

| AF013 |

The crosshead moves to a limit switch, force set point, travel position, or break, then stops and reverses direction at full speed to the opposite limit. |

- If reversing at force set point: Series 7 or 5 gauge or indicator with load cell, and 09-1214 interface cable

- If reversing at travel limit: AF011 programmable travel limits option

- If reversing at break: AF019 break detection option and 09-1214 interface cable

|

| AF014 |

Same as auto return, but with the ability to program up to 100,000 cycles. Programmable dwell time for upper and lower limits (set independently) can be set up for up to 10,000 seconds. |

- Same as auto return, at the same speed in each direction. Add AF016 for independent up and down speeds.

|

| AF016 |

Configurable speeds for up and down directions. |

– |

| EF017 |

Extends the standard speed range down to 0.02 in/min (0.5 mm/min). |

– |

| AF018 |

Extends the standard speed range up to 45 in/min (1,100 mm/min). |

– |

| AF019 |

Crosshead stops at a sudden drop in force. Programmable percentage of peak force. |

- Series 7 or 5 gauge or indicator with load cell

- 09-1214 interface cable

|

| AF020 |

Dynamically adjusts the crosshead position to maintain a programmed load for an indefinite or specified period of time. |

- Series 7 or 5 gauge or indicator with load cell

- If a specified time is required, add AF014 cycling / dwell time option

- 09-1214 interface cable

|

| AF021 |

Stops the crosshead and/or zeroes the travel display at an initial preload – useful in tensile, compression, spring, elongation, and other applications. Preload is programmable as a percentage of force gauge/load cell full scale. Three modes: (1) stop, (2) stop and zero, and (3) zero without stopping. |

- AF009 travel indication

- Series 7 or 5 gauge or indicator with load cell

- 09-1214 interface cable

|

| AF022 |

Save and recall sets of test parameters, such as speeds, travel limits, preloads, etc. Up to 50 profiles may be stored. |

– |

| AFCOMP |

Includes all functions listed above, plus 09-1214 interface cable and 09-1158 USB cable. Requires a Series 7 or 5 gauge or indicator with load cell. |